IEC 61131: Standard for Industrial Automation Programming

Industrial automation relies heavily on IEC 61131, an international standard that defines common programming languages for programmable logic controllers (PLCs). This comprehensive guide provides an overview of IEC 61131 and explains why it is so vital for industrial automation engineers.

Article Outline

- What is IEC 61131, and Why is it Important?

- A Brief History of IEC 61131

- The Different Parts of IEC 61131

- Key Benefits of Using IEC 61131-3

- Programming Elements in IEC 61131-3

- Implementing and Debugging IEC 61131-3 Programs

- Understanding the Scope of IEC 61131

- Key Takeaways on the Importance of IEC 61131 Standards

What is IEC 61131, and Why is it Important?

IEC 61131 is an international standard that establishes common programming languages and standards for programmable logic controllers (PLCs), which are computers used to automate industrial processes. Also known as the “PLC programming standard”, IEC 61131 aims to standardize PLC software development to benefit both machine builders and end-user companies.

There are several key reasons why IEC 61131 is important:

- It allows PLC code to be portable and reusable across hardware platforms. Without IEC 61131, PLC software would be vendor-specific.

- It enables reducibility in hardware costs and software development time.

- It promotes simpler integration of components from different manufacturers.

- It defines protocols for communication between software tools, reducing errors.

Conforming to the IEC 61131 standard is crucial for any organization involved in industrial automation because it offers significant technical and economic advantages.

A Brief History of IEC 61131

The IEC 61131 standard for PLC programming originated in the 1990s from a European initiative called PLCopen. Early PLCs lacked standardized programming languages, hampering the transportability of programs between PLC hardware.

To address this, IEC 61131 was formed to define:

- Common PLC programming models

- Compatible graphical and textual programming languages

- Common terminology and concepts

The first edition was released in 1993. The IEC 61131 standard has continued to evolve, with the 3rd edition released in 2013 containing updated programming model specifications.

The Different Parts of IEC 61131

IEC 61131 currently contains ten parts, the key among them being:

- Part 3: Defines common programming languages for PLCs

- Part 4: User guidelines

- Part 5: Communication

- Part 7: Fuzzy control programming

- Part 8: Guidelines for life cycle handling

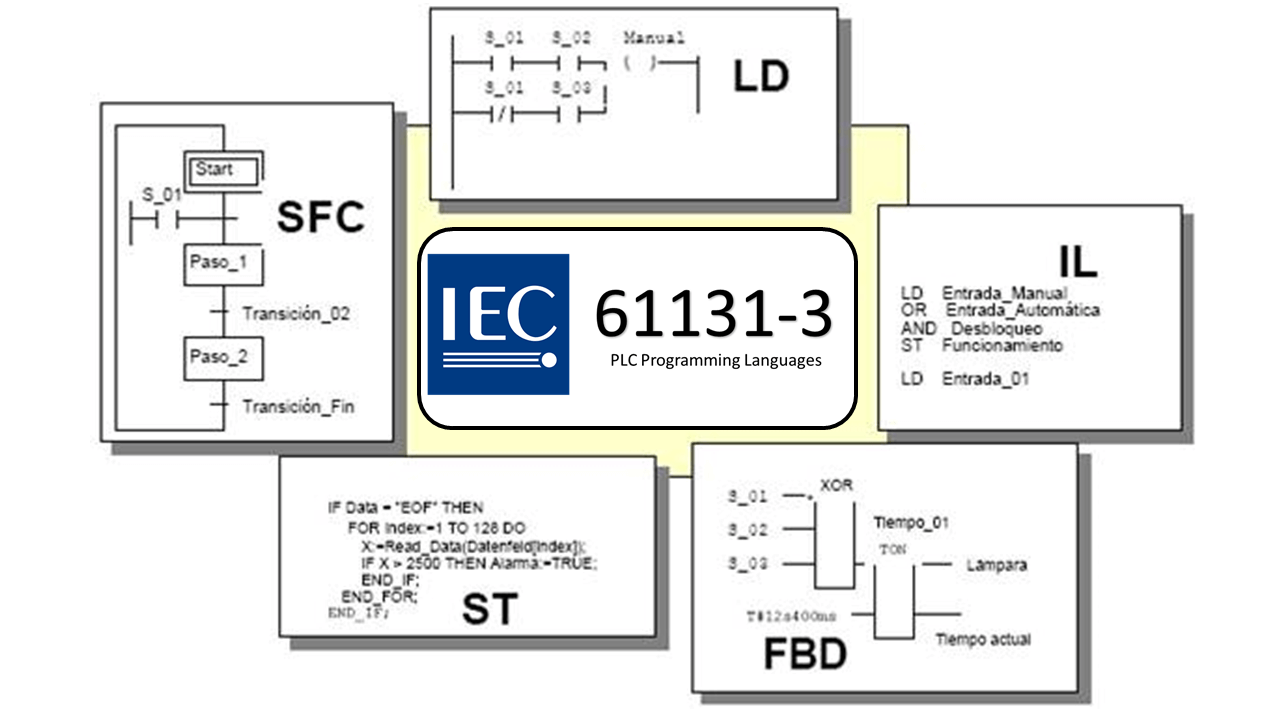

Part 3 plays a central role in harmonizing PLC software development via five standardized programming languages:

- Ladder Diagram (LD): Graphical, represents sequential functions

- Function Block Diagram (FDB): Graphical, combines data and functions

- Structured Text (ST): Textual language with Pascal-like syntax

- Instruction List (IL): Textual, assembler-like programming

- Sequential Function Chart (SFC): Graphical language that represents program organization units (POUs) and transitions

These five programming languages allow automation engineers to select the best approach for their application or even combine multiple languages within a program.

Key Benefits of Using IEC 61131-3

Some major advantages of using the IEC 61131-3 programming standard include:

- Portability: Programs can easily migrate between PLC hardware

- Reusable code: Function blocks enable reuse instead of rewriting code

- Reduced coding errors: Strongly typed variables lessen bugs

- Productivity: Graphical and textual language options fit varied programmers

- Enforces discipline: Standard defines clear modeling constructs

Additional benefits are reduced training requirements, easier troubleshooting, and stronger integration across vendor hardware and software components involved in industrial automation projects.

For example, peripheral devices like HMIs can integrate more seamlessly with control programs if both conform to IEC 61131 principles. Functions and function blocks also streamline tasks like advanced PID control by encapsulating complex calculations into reusable code blocks with defined interfaces.

Adopting IEC 61131 enables organizations to maximize returns on their industrial software and equipment investments.

Programming Elements in IEC 61131-3

To leverage the strengths of IEC 61131-3, it helps to understand key elements of PLC programs:

- Data types: Bool, bitstrings, integer, real, timers, etc.

- Variables: Typed data storage

- POUs: Program organization units like functions or function blocks

- Functions: Code blocks without internal memory

- Function blocks: Code blocks with persistent internal memory

The data types include simple types like Booleans and integers and derived types like STRING and arrays. Each element serves a role in the programming process.

For instance, function blocks act as modular pieces of logic that can be configured, saved, and reused. Defining clear interfaces minimizes the unnecessary sharing of internal details. This encapsulation and information hiding lend itself well to object-oriented programming concepts.

Constructing programs from standardized elements using IEC 61131-3 languages encourages modular and maintainable code.

Implementing and Debugging IEC 61131-3 Programs

Once code is written, configuration and debugging tools allow loading programs onto PLCs and interfacing with sensors, drives, HMI panels, and other automation components.

Vendors supply 61131-3 programming suites for tasks like:

- Configuring hardware I/O

- Setting up communications

- Animating program flow

- Monitoring variables and memory

- Debugging runtime errors

These Windows-based software packages provide ladder logic editors, simulation capabilities, and connectivity to PLC targets. This facilitates tasks ranging from validation testing to troubleshooting flaws in complex sequences.

Strict conformance to IEC 61131-3 ensures engineers can reuse skills and code on any standards-compliant platform. So, knowledge gained on one vendor’s system transfers readily to others.

Understanding the Scope of IEC 61131

The standard applies specifically to programmable logic controllers and related software tools. But it does not cover several related areas:

- Electrical safety: Addressed by IEC 61131-2

- EMC requirements: Covered in IEC 61326 series standards

- Performance metrics: Found in ISO 13849 and IEC 61508

So, while extremely useful for functional industrial software development, IEC 61131 does complement some other standards for complete system certification.

Key Takeaways on the Importance of IEC 61131 Standards

- IEC 61131 establishes common languages for PLC programming

- It offers major reusability, portability, and integration benefits

- Part 3 languages like Ladder Logic are now globally well-understood

- Programming elements like function blocks encourage modular code

- Conforming debugging tools ease development and troubleshooting

Standardized PLC software engineering is a major enabler of cost reduction, improved safety, and productivity for the industry. Mastering IEC 61131 principles and languages provides automation professionals with transportable skills that enable world-class digitalization.

About Us at Automation Ready Panels

Welcome to Automation Ready Panels, your premier destination for top-tier electrical control panels and automation solutions. With over two decades of rich experience in supporting manufacturing industries, from machine builders to process facilities, we have established ourselves as leaders in delivering high-quality, pre-built, and pre-programmed control panels. Our expertise ensures the swift and efficient handling of even the most complex panels, incorporating cutting-edge technology.

Why Choose Us?

- Tailored Solutions: We believe in solving customer pain points. Our approach focuses on identifying the “Job to be Done” designing hardware and software specifically to alleviate your challenges.

- Rapid Installation: We provide comprehensive setups, including network switch, VFD/Servo drive, HMI programming base, and PLC programming base logic. This enables quicker installation and startup, offering a seamless, vertical-like experience.

- Unmatched Quality: Quality is paramount in our manufacturing process. Each step undergoes rigorous quality checks, significantly reducing errors and ensuring consistently superior control panels.

- Thorough Testing: Before shipping, every panel undergoes extensive electrical and software testing, covering aspects like Electrical Continuity, Voltage, Grounding, Circuit Function, System Functions, and Software Testing.

Connect With Us

Ready to elevate your manufacturing process with our state-of-the-art control panels? Contact us at Automation Ready Panels today to explore how we can help you achieve efficiency and quality in your operations. Let’s transform your automation experience together!

SHOP NOW

-

Large Process Automation: Panelview 5000, ControlLogix 5580

$21,389.00 Select options -

Small Process Automation: Panelview 5000, ControlLogix 5580

$17,999.00 Select options -

Small Process Automation: ControlLogix 5580, UPS Battery Backup, Cellular Modem

$16,999.00 Select options -

Advanced Automation: Panelview 5000, Safety CompactLogix 5380

$8,499.00 Select options