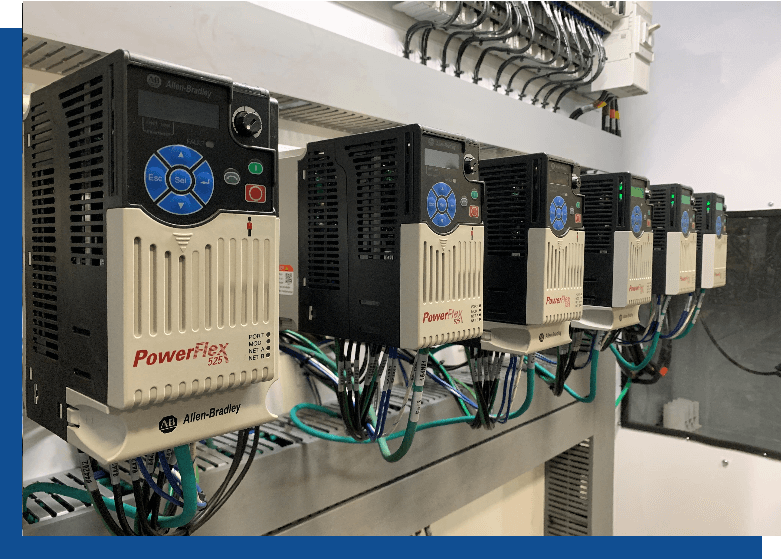

The VFD Panel with Room to Grow

This is the one-design fits all VFD panel. Say good-bye to restricted functionality, minimal capabilities, or limited number of VFDs. Our VFD Panels have:

- The latest 21st century VFD technology

- Three VFD models to choose from

- All smart devices are networked on Ethernet/IP or Modbus for connectivity

- Advanced programming code capabilities

- Modern Safe-Torque Off safety system is embedded and can be flexibly programmed (Powerflex 520 series)

All You Need to Know about a VFD Panel

VDF, an abbreviation of Variable Frequency Drive, is essential for every

production facility. The continual operation of VFDs maintains a plant's output. If it fails, a chain reaction effectively halts the whole industry. Manufacturing plants are known for their harsh working conditions, including grime, wetness, and corrosion. Variable Frequency Drives (VFDs) can be enclosed in shielding covers, but they still need safety from the elements and a complete enclosure for all connected equipment. This is why buying a fully designed VFD Panel is important for any plant.

In General, the Variable Frequency Drive Panel, usually referred to as the VFD Panel, is used to regulate the speed of electric motors.

Pumping, drilling, and other major machine applications such as conveyors and compressors make extensive use of them.

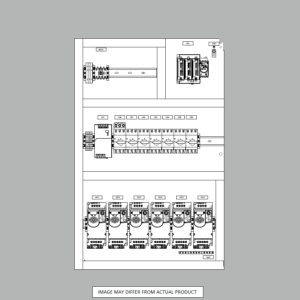

What is Typically Inside a VFD Panel

A VFD Panel can have a variety of parts. Here are some instances of what you could come across:

- VFD: It is the motor control panel's central part. The hp, voltage, total load amps (FLA), and other parameters of the VFD within will vary.

- Line reactors: Its purpose is to decrease harmonic distortion by 3% or 5%.

- Harmonic filters: This is also another yet more helpful method of decreasing harmonic distortion.

- Circuit breaker: It aims to prevent excess or short circuits in an electrical circuit.

- Bypass: This is installed to ensure that the system continues to run even if the VFD fails.

- Programmable Logic Controller (PLC): It is installed in case you have more complex processes or control conditions required

- Modem: For communications from the VFD to the PLC, HMI, or other connected systems.

- Air conditioning or other cooling equipment: They are to maintain a set temperature for the panel based on the adjoining

environment.

Benefits of a VFD Panel

The following are a few of the many benefits VFD Panels offer:

- Energy Savings: In factories, electric motors utilize more than 65 percent of the energy. Motors that have speed flexibility and do not need to run at full speed can be set to a lower speed and consume less power. As a result, these VFDs save a significant amount of electricity.

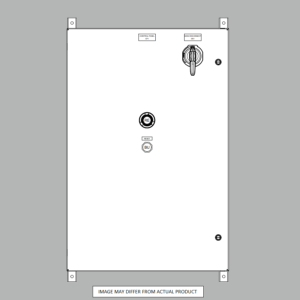

- Power switching and protection: VFD panels are typically equipped with a circuit breaker directly linked to the input line power supply. This circuit breaker (or a separate fused rotary disconnect) is used to turn the panel on and off. Also, it offers safety in the event of overload in the motor circuit due to a short circuit event. VFD panels can also detach power to shield the operator during a motor repair or unsafe condition using advanced safe-torque off safety circuits.

- Adjustable speed: A frequency control potentiometer is located on the VFD to reduce or increase motor speed for the application. Alternatively, a signal can be sent from the PLC according to the operator's preferences or from closed-loop control logic.

- Smooth operation: VFDs provide seamless start-up and stop-up operations using controlled acceleration and deceleration. That smooth operation means they reduce thermal and mechanical stress on belt drives, gear boxes, direct drives, etc.

- Visual Diagnostics: Several indicators from the VFD provide the operator with real-time information regarding the power the drive consumes and other diagnostic data, such as: frequency, amperage, and fault codes. Controls are also built to let the operator take preventative action based on the observed readings like high amperage, etc.

Our VFD Panels Bring Value to Your Operations

The Bottom Line: VFDs (Frequency Variable Drives): industrial plants would be incomplete without them. They bring flexibility, smooth operations, energy savings, diagnostics, and many other must-have capabilities to today's 21st century factory. Talk with our experienced and knowledgeable engineers today if you would like more information on our VFD Panel designs.