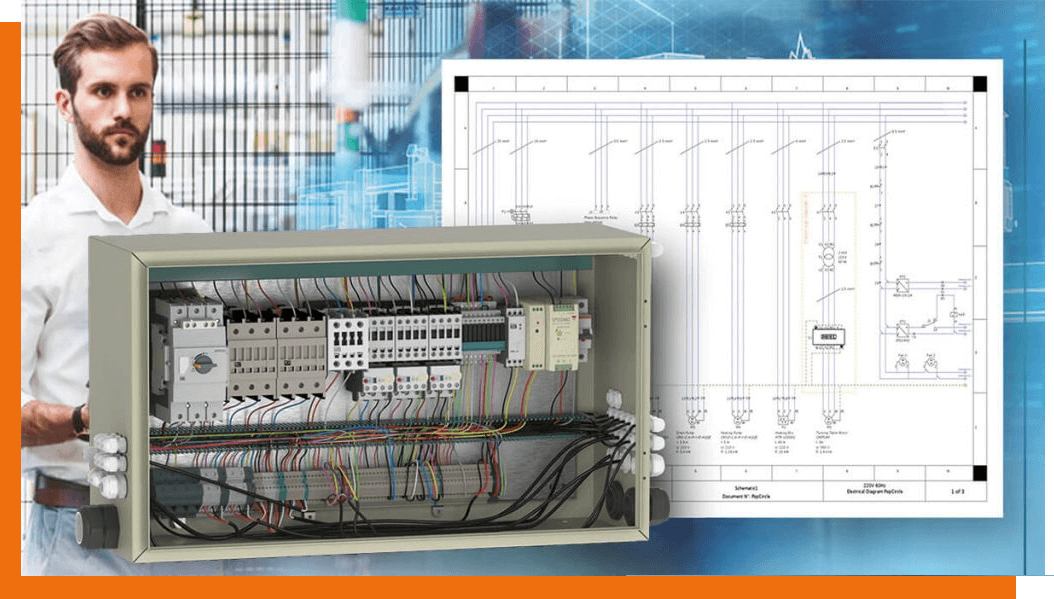

Our Panel Shop

Understand the complex ins and outs of world-class industrial control panel shops.

Every company or individual will have different needs for their PLC Panel. However, there are some panel shop gold standard practices to look out for, generally speaking. No two PLC Panels will be exactly the same, and that’s part of their business value. But, for the best panel shop, they are assembled and wired with the quality and consistency of building any standard design over and over.

Start with Quality Standard Drawings

Having standards pertaining to panel layout and wiring ensures that our panels provide familiar and repeatable work. This means that quality and speed increase, over time, for every panel built. There are usually a lot of commonalities between each PLC Panel, which provide the opportunity to build lean processes around each step in the assembly and checkout process.

Stock Inventory in the Panel Shop for Common Components

Similarly, our panel shop carries the common components used for every standard design, allowing for faster reaction to customer's orders and short lead-times. Typically, 70% of the components in each panel type are stored. This reduces risk when there are supply chain disruptions.

Create Panel Shop Efficiency by Reducing Waste

Utilizing Lean Product Development (LPD) and Lean Production System (LPS) allows our production work cells to create standard work, tact, one piece flow, and zero defect. Creating a Plan, Do, Check, Act operating system provide for Continuous Improvements in the process and products. This again brings the value of speed to market and reduced cost to every customer that purchases our panels.

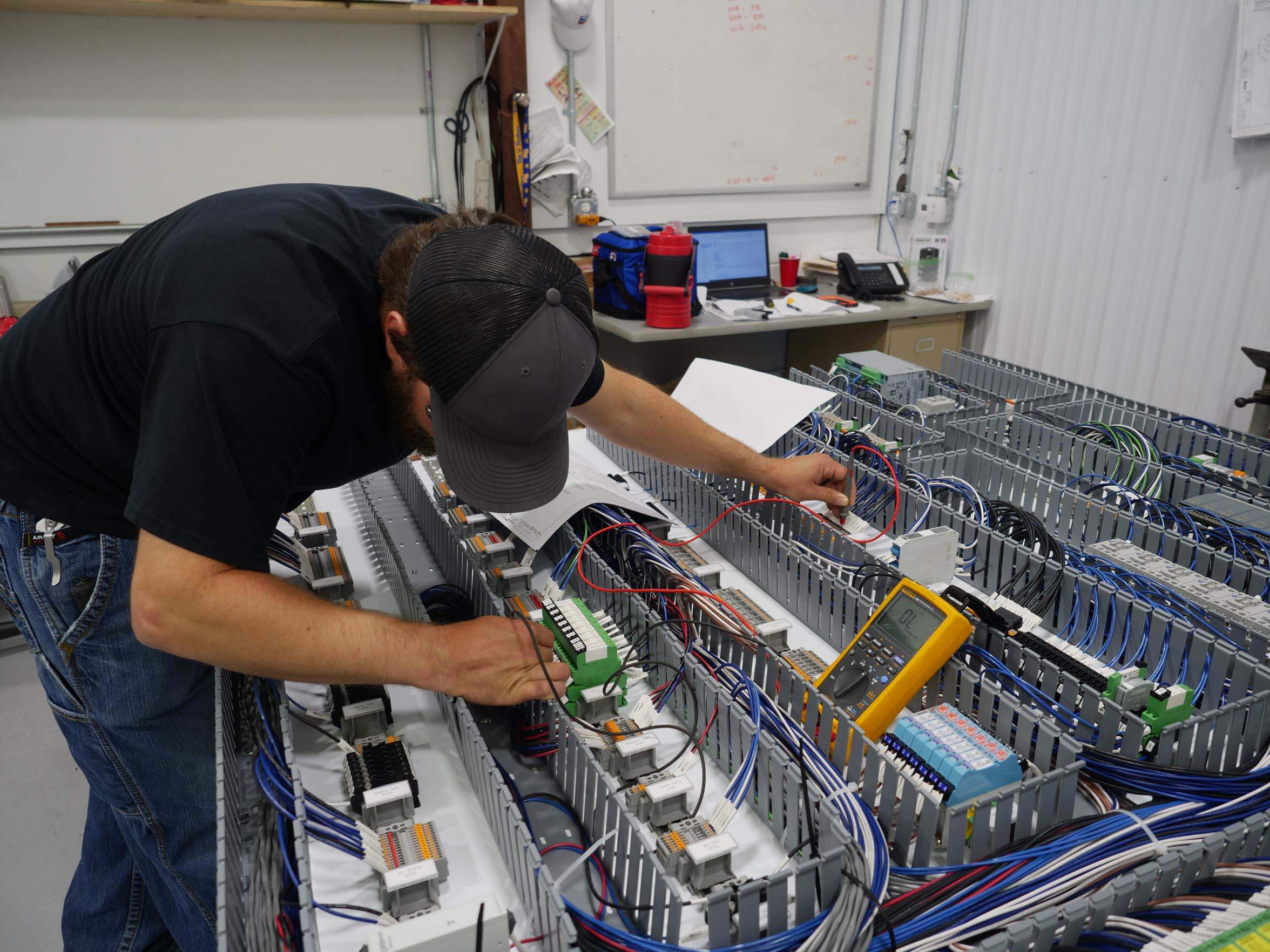

Include Quality Checks during Panel Assembly, Power Up, and Checkout

When operating an industrial equipment fabrication center; safety, productivity, efficiency, and quality are top priorities. In-fact, they are our KPI metrics. We manage quality in every work cell, providing little to no rework and the end-of-line quality testing. Our priorities are not based solely around tactical process execution, we live by prioritizing people first, then quality, delivery, and cost, in that order. This keeps our focus on whats most important to us, the people that make our success possible.

Designing, building, and testing industrial equipment and PLC Panels can be incredibly rewarding. When our fabrication operations are running smoothly, our people feel satisfied knowing that they put in the work to make everything right. Understanding these key concepts used in our panel shop ensure that your purchasing the right PLC Panel for your industrial facilities. If you’re ready to purchase PLC Panels, please shop now or contact us. With our world-class industrial control panel shop, we can help!