Programmable Logic Controllers Will Benefit Your PLC Applications

Standard Automation PLC control panels are increasing functionality and machine/process optimizations around the world. These industrial controllers are easy to use with customizable capabilities for different functions and operations across a variety of industries and PLC applications. Allen-Bradley designed this PLC platform to be used for large standalone machines, but Automation Ready Panels has expanded it's capabilities with built-in code to communicate with other Allen-Bradley PLCs and products, along with third-party products like SMC ethernet valve banks. Each model is designed with the Ethernet/IP network protocol to enable you to have the perfect controller for your expanding communication and integration needs.

These innovative PLC control panels can be connected with other devices and software to maximize the visibility and efficiency of your industrial operations. Whether you operate a mail service where quickly and accurately sorting packages is essential, or you have a series of stamping press machines, these PLCs can easily and effectively connect to your network and increase productivity with unbelievable ease.

For an overview of this PLC platform, watch Rockwell Automation's quick Micro800 video to discover the automation possibilities.

Other Great PLC Applications for our Control Panels

PLC Control Panels can be applied to a number of industrial purposes. With flexible network connectivity and a standard ease of use, you’ll achieve the right amount of control capability for any operation and quickly maximize efficiency.

- Packaging Operations

- Material Handling Lines

- Converting, Print, Web Production

- Process Skid Systems

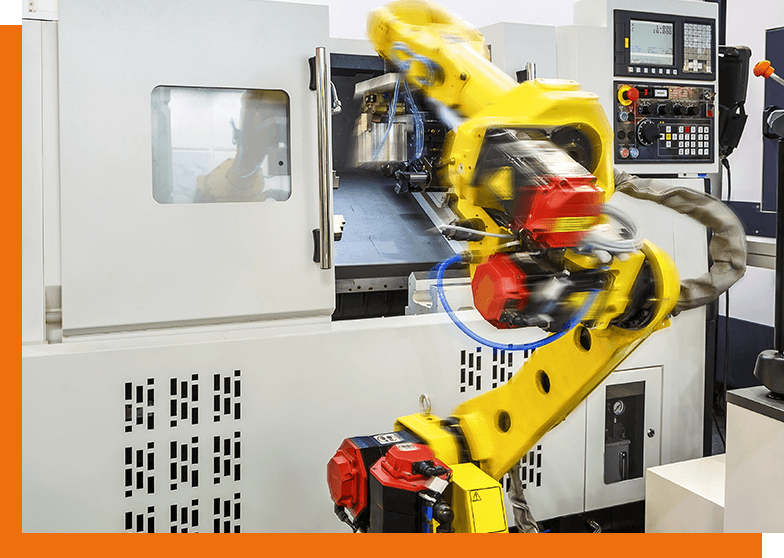

- Manufacturing and Assembly Lines

- Solar Energy

View this brochure to learn more about PLC control panels and a range of accompanying products to aid in your industrial operations.

PLC Control Panel Application for Packing Operations

Intermittent Vertical Form Fill Seal (VFFS) machines package everyday products. These machines must accurately detect where to cut and seal each package at incredibly high speeds as they’re filled with materials. Typically, some sort of marker such as a logo will indicate the dimensions of the packaging to notify when the machine will cut and seal each individual package.

PLC Control Panels are fundamental for this process, as they control how the system operates and make management more efficient. The touch probe is a motion control feature to precisely detect each marker and notify the web puller when to stop. Because these PLCs function on separate hardware, the motion is separate from the scan, which means you can achieve a higher production level without sacrificing quality.

PLC Control Panel Application for Material Handling

Material handling allows packages to be distributed from one location to another easily and quickly, such as organizing boxes for different distribution centers or moving one product from one main conveyor line to a sub-conveyor.

The PLC control panel will be the hub of your system, with other software and systems reporting back to the controller. The PLC will quickly calculate when each package is in the correct position on the main conveyor belt to be pushed to another line and will then signal the actuator to push the package to the new conveyor belt. Network diagnostics are available to pair with the PLC control panel which can help with lowering start-up times, maintenance, and downtime, thus increasing productivity.

PLC Control Panel Application for Remote Water Systems

PLC Control panels can also be applied to remote systems that can be managed through data connection. This allows the water system to operate even if the water tank and pump are miles apart and can be managed without an operator physically being on-site. These PLC control panels offer the ultimate level of convenience.

This system works by one panel detecting the water level and another powering the pump on and off. As it uses cellular data, it requires minimal installation costs as well as lower operation costs since it uses SMS messaging. Status updates will be sent to the operator’s cell phone. This allows the operation to continue running smoothly and autonomously. The system diagnostics and status is also shown on LCD displays that are attached to each PLC control panel.

Maximize Efficiency and Productivity Today!

PLC control panels can drastically increase efficiency and productivity for your industrial operation. PLC control panels can be used for a wide variety of applications. Your business will only benefit from this incredibly easy-to-use technology. Say goodbye to wasted downtime and inaccurate production — invest in a high-quality PLC control panel from Automation Ready Panels today. Shop Online Now!