What is an Encoder

What is an Encoder?

So, what is an Encoder? Motor encoders are electronic devices that are used to monitor the position and speed of a motor. They play an important role in many industrial and automated systems, as they provide precise and accurate information about the motion and position of a motor. In this article, we will discuss how motor encoders work and the different types of encoders available.

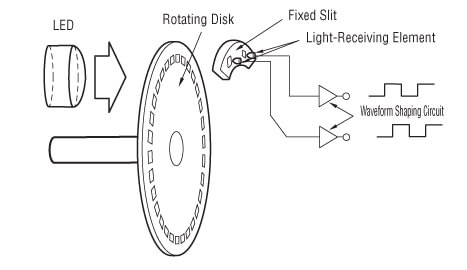

A motor encoder consists of two main components: a sensor and a code wheel. The sensor is usually a photodiode or an optical sensor that detects light and generates an electrical signal. The code wheel is a disk that has a series of transparent and opaque sections or lines. The code wheel rotates with the motor shaft and the sensor detects the light passing through the transparent sections, generating an electrical signal that is proportional to the position of the motor shaft.

There are two main types of motor encoders: absolute encoders and incremental encoders. Absolute encoders provide a unique digital code for each position of the motor shaft, allowing the system to determine the exact position of the motor at any given time. Incremental encoders, on the other hand, generate pulses or signals that are proportional to the motion of the motor. These pulses are used to determine the speed and direction of the motor.

Absolute encoders are commonly used in applications where precise position control is required, such as in robotic systems, motion control systems, and automation systems. They provide a higher level of accuracy and reliability compared to incremental encoders, as they are not affected by power failure or system restart.

Incremental encoders are widely used in applications where speed and direction monitoring is required, such as in conveyor systems, machine tools, and material handling systems. They are cost-effective and easy to install, and can provide a high level of accuracy and reliability if used correctly.

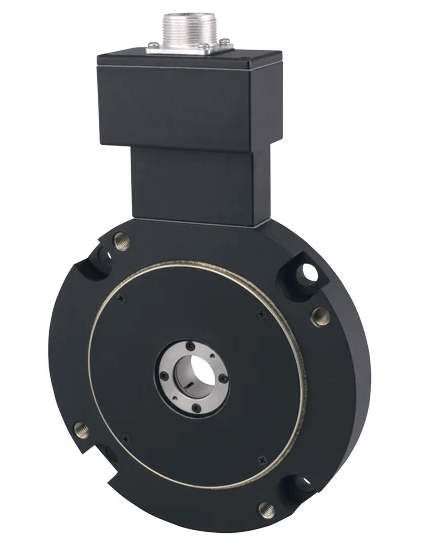

One prominent encoder supplier is Dynapar. Dynapar has the world’s largest product range of encoders, resolvers and accessories for motion feedback control.

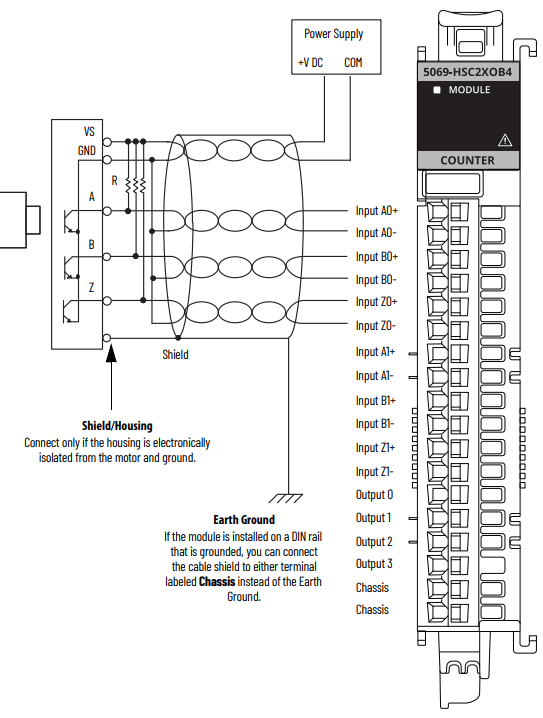

For the PLC input, High-Speed Counter (HSC) modules are used. Below is a wiring example for a single-ended encoder. They typically require supply voltage wires and signal wires. Sometimes, if the encoder is pulsing backward and the encoder is counting down instead of up, A0+ and B0+ can be swapped.

In conclusion, motor encoders play an important role in many industrial and automated systems, providing precise and accurate information about the position and speed of a motor. Absolute and incremental encoders are the two main types of motor encoders, each with their own unique features and applications. By understanding the principles of how motor encoders work, engineers and technicians can make informed decisions about which type of encoder is best suited for their specific application.

Wanting to dig deeper into the question What is an Encoder? Need to bounce your questions off an expert? Contact Us

SHOP NOW

-

Large Process Automation: Panelview 5000, ControlLogix 5580

$21,389.00 Select options -

Small Process Automation: Panelview 5000, ControlLogix 5580

$17,999.00 Select options -

Small Process Automation: ControlLogix 5580, UPS Battery Backup, Cellular Modem

$16,999.00 Select options -

Advanced Automation: Panelview 5000, Safety CompactLogix 5380

$8,499.00 Select options