PackML: The Packaging Machine Language Driving Automation

PackML is an automation standard developed by OMAC and adopted by ISA as TR88.00.02. It provides a common “look and feel” and unified machine state control for packaging machines. As manufacturing becomes more automated, standards like PackML make it easier to transfer and retrieve consistent machine data, troubleshoot issues, and integrate machines, driving improved overall equipment effectiveness (OEE).

In this comprehensive guide, we’ll cover:

- What is PackML, and who created it

- The goals and benefits of implementing PackML

- Key components of the PackML state machine model

- Steps for using PackML on packaging machines

- Integrating PackML with other systems

- The future of the standard

Understanding PackML is key for anyone looking to improve automation and OEE in packaging operations. Read on to learn how this machine language can drive interoperability!

What is PackML, and Who Created It?

PackML stands for Packaging Machine Language, a set of software standardizations for automated packaging machines and equipment. It was created by the Organization for Machine Automation and Control’s (OMAC) Packaging Workgroup, which comprises manufacturing companies, suppliers, system integrators, and technology providers seeking to drive more effective automation.

The primary goals of PackML are to:

- Standardize machine control software for easier integration

- Simplify tech troubleshooting between components

- Establish a common “look and feel” HMI for operators

- Make machines easier to operate and maintain

First published in 2005, PackML aligns with the ISA 88 batch process control standard for continuous and discrete processes. The latest version is detailed in the IEC/ISA technical report ISA-TR88.00.02-2022. This document and related specifications make up the standard set of PackML guidelines.

To download the PackML standard, please visit the ISA website.

Why Implement PackML on Packaging Machines?

There are several key benefits to utilizing the PackML framework to standardize machine control:

Improved Integration Between Packaging Machines

PackML establishes naming and coding conventions for automation components like I/O signals, recipes, and alarms. This makes integrating controls and transferring data between PackML conformant machines from different vendors far easier.

Easier Troubleshooting and Maintenance

Technicians can more quickly diagnose issues and maintain machines since PackML provides standard component names, architectures, state models, and interfaces. It reduces the need for vendor-specific knowledge.

Higher Overall Equipment Effectiveness (OEE)

Easier integration means faster changeovers, reduced downtime during maintenance, quicker troubleshooting, and more consistent quality and output. All of this translates to higher OEE.

More Transferrable Operator Knowledge

Since the HMI look and feel is standardized between machines, operators don’t need to re-learn new systems when machines are changed on a production line. Their expertise becomes transferable across packaging equipment.

Implementing the PackML framework drives significant operational benefits in packaging automation!

Key Components of the PackML State Machine Model

The PackML State Model

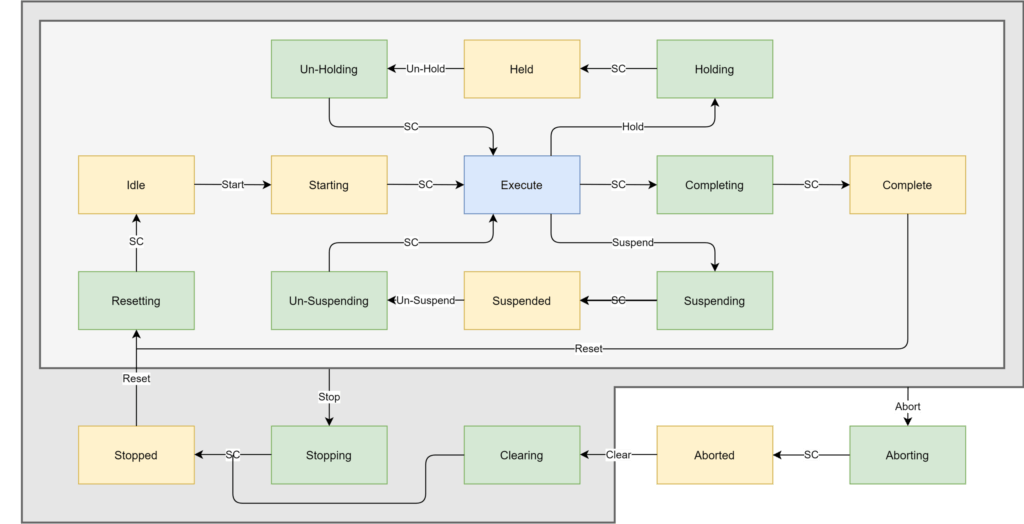

At the core of PackML is its state machine model, which defines machinery behavior through modes, states, actions, and state transitions. Understanding the state model is crucial for working with PackML.

The main components of the state machine include:

- Modes – Categorize general machine operating conditions (e.g., automatic, manual, maintenance)

- States – Define specific status within a mode (e.g., starting, executing, holding)

- Actions – Things machines do when enabled (e.g., jog, cycle, abort)

- Transitions – Change between states

There are eight primary execution states under the automatic operating mode. As machines run, they transition between these states:

- Stopping

- Stopped

- Starting

- Execute

- Suspending

- Suspended

- Unsuspending

- Resetting

Being in a defined state (like Execute or Suspended) provides the discrete control modules information on what the machine is doing. Standardizing these statuses and the state transitions enables smoother coordination between connected machines and systems.

How to Implement PackML on Packaging Machines

Deploying PackML machine control requires aligning with the established standards and state models within the IEC/ISA technical specifications. Some key steps include:

Map All Machine Operations to PackML States

All major machine operations and transitional statuses must correspond to a defined PackML state. Additional custom states can be created if necessary. This ensures standardized control of packaging machines.

Name Components Using PackML Conventions

I/O signals, alarms, recipes, and other coding elements must follow naming rules outlined by PackML to enable integration.

Structure HMIs Around PackML Architecture

The HMI display layout and visual language should conform to the standard look and feel. This provides a consistent machine interface for operators across different equipment.

Configure Controller Architecture for PackML

Controllers running machines should execute state model transitions, track statuses, and activate actions according to the PackML framework. This controls machinery per the standard.

Following these steps and the technical guidelines allows machines to become PackML conformant.

Integrating PackML Machines with Higher-Level Systems

On top of integration between packaging machines, adopting PackML also enables easier coordination with plant floor systems:

SCADA Platforms

PackML machine data, including statuses, cycles, production counters, and downtime events, can be monitored more readily through SCADA software.

MES Software

Manufacturing Execution Systems can pull PackML production data to optimize production scheduling, asset utilization, preventative maintenance, and more across the facility.

ERP Systems

PackML machines can roll up OEE metrics and production counts to ERP software to track enterprise performance.

Standardization enables automation data to be leveraged more effectively across the Smart Factory ecosystem.

The Future of PackML Standardization

As PackML becomes more widely adopted in new machine design and retrofits, the standard is likely to continue evolving:

- Expansion into continuous process manufacturing applications

- Additional modules like PackSafe for safety and PackConnect for IIoT communications

- New implementation guides for technology, such as motion control

- Growth of ISA and OMAC conformance testing programs

Wider adoption, new modules, and conformance testing will solidify PackML as a core automation standard alongside technologies like EtherNet/IP. This drives major OEE gains!

Real-Life Example of Leveraging PackML

For example, a food manufacturer upgrades their packaging line to add an automated bagger unit and existing carton-forming equipment.

The new automated bagger controls are designed to the PackML standard, including modeling machine states Starting, suspending, executing, and stopping. Meanwhile, the former carton also updated its PLC code to become PackML conformant.

Now, the discrete control modules on both machines can seamlessly coordinate activities and share interlock data. The packaging line’s SCADA software can also easily monitor the line for statuses and track overall equipment effectiveness (OEE) with standardized data.

The updated PackML machines also provide a common look and feel on their machine interface panels. Operators can work across all packaging units with consistent language and controls without re-learning different systems.

Leveraging PackML alignment for new automated machines like the bagger reduces integration complexity. This helps avoid issues like starving upstream carton-forming processes when units are stopped or jammed. Material flow and data sharing between equipment are also smoother.

Key Takeaways on the PackML Machine Control Standard

Implementing the PackML automation standard provides measurable improvements in integration, productivity, flexibility, and operational efficiency. Key points:

- PackML drives interoperability between packaging machines

- Conformant HMIs establish a common machine language for operators

- Standard component naming simplifies troubleshooting/maintenance

- Adoption leads to higher overall equipment effectiveness

- Integration with SCADA

Get to know more about the PackML standard and how our automation systems are related to it. Contact us today at Automation Ready Panels.

SHOP NOW

-

Large Process Automation: Panelview 5000, ControlLogix 5580

$21,389.00 Select options -

Small Process Automation: Panelview 5000, ControlLogix 5580

$17,999.00 Select options -

Small Process Automation: ControlLogix 5580, UPS Battery Backup, Cellular Modem

$16,999.00 Select options -

Advanced Automation: Panelview 5000, Safety CompactLogix 5380

$8,499.00 Select options